Ship to Shore Port of Townsville crane assembly

Universal Cranes provided equipment transportation, manned crane hire, and lift engineering for the Ship to Shore crane assembly.

Wm. O’Brien

Liebherr Container Cranes

Ship to Shore Crane Assembly at Port of Townsville

2021

TBA

2 x Liebherr LR1300

Liebherr LTM1120-4.1

Liebherr LTM1130-5.1

Grove GMK5220

SCOPE

- Transport equipment

- Manned crane hire + riggers

- Supply of miscellaneous equipment (temp rails etc)

- Lift Supervisor on site for duration of project

- The project was finished early 2021 with a variety of Universal Cranes’ cranes used including the Liebherr LR1300, Liebherr LTM1130-5.1 and Grove GMK5220.

OVERVIEW

Townsville: In early 2021, Universal Cranes completed the Ship to Shore Crane Installation for Wm. O’Brien for end customer Liebherr Container Cranes. The Project involved installation of two Ship to Shore cranes at the Port of Brisbane and Port of Townsville. This submission focuses on the Townsville component of the project.

Universal Cranes was engaged by Wm O’Brien to provide cranage, operators, riggers, on-site supervision and lift engineering support for the erection of Liebherr’s Ship to Shore container crane.

The installation at Port of Townsville is the final element of the $30million upgrade to its multi-user cargo handling facility. Standing at almost 100m, the blue and gold corporate colours of the Liebherr Super Post Panamax Ship to Shore Crane transforms Townville’s skyline.

Painted in the Port of Townsville’s blue and gold corporate colours the crane will cut a striking figure on the city’s skyline. It also offers superior handling ability, with the capability to lift two 20-foot shipping containers at once equating to 70 tonnes.

Port of Townsville Infrastructure and Environment General Manager Marissa Wise said the assembly of the ship-to-shore crane would support up to 15 full-time jobs for locals during construction.

“Contractors from Townsville-based Universal Cranes will support the assembly, which will take several months, and include positioning the crane on the wharf and completing a series of safety and operational checks,” said Ms Wise.

Transport and Main Roads Minister Mark Bailey said the crane will comfortably double the operational speeds of its predecessor.

“The new Crane and Cargo Terminal is able to unload vessels at a rate of 35 twenty-foot equivalent containers per hour,” Mr Bailey said.

DESCRIPTION OF THE LIFT

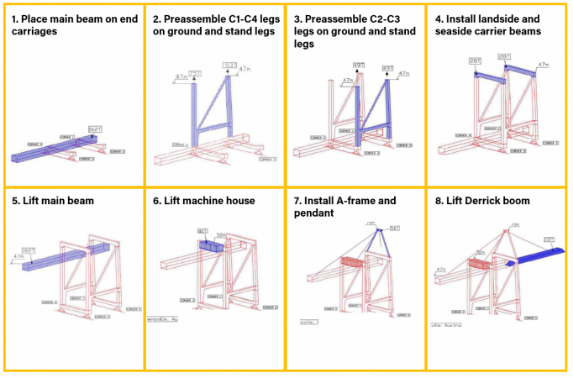

With all equipment and personnel now on-site, the critical lifts and assembly works commenced following the below sequence;

- Place main beam on end carriages

- Preassemble C1-C4 legs on ground and stand legs

- Preassemble C2-C3 legs on ground and stand legs

- Install landside and seaside carrier beams

- Lift main beam

- Lift machine house

- Install A-frame and pendant

- Lift Derrick boom’

LIFT COMPLEXITY

In addition to the general craneage and transport services, Universal Cranes was able to provide a number of additional services and solutions to the client including;

- Supply of no.80 timber bog mats

- Supply of no.20 80t, 1m stools

- Design and fabrication of temporary crane rails

- Fabrication and certification of lifting lugs

- Supply of cyclone ballast

- Site offices

- In-house engineering and lift planning

- On-Site supervision

- Rigging

SITE CONDITIONS

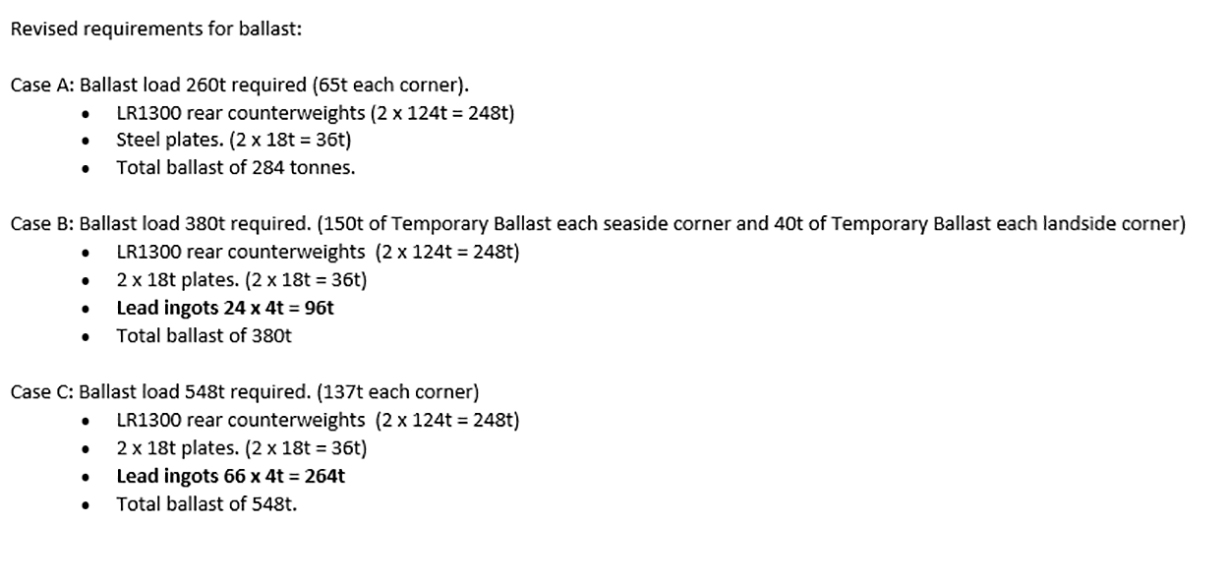

Due to Townsville’s geographical location, between the months of December and April the area is subject to bursts of monsoonal rains and tropical cyclones are a real threat. Therefore a contingency for such scenario was planned. Working with Liebherr and the Port of Townsville, Universal Cranes was able to prove additional ballast required to tether the STS crane safety in the event of a cyclone. There were three scenarios provided at various stages of construction.

On the 18th of January 2021, a tropical cyclone warning was issued by the Australian Bureau of Meteorology, Tropical Cyclone Warning Center for areas stretching from Innisfail to Ayr which included Townsville. At that time, the Port of Townsville moved into Condition Orange – Extreme Weather Event Warning – Response.

Universal Cranes worked quickly with WM O’Brien and Port of Townsville to create a checklist of preparation activities in readiness for the impending cyclone. We only had a day to safely secure the site before the cyclone was due to hit.

Once actions were agreed upon, Universal Cranes crew members secured:

- STS crane and components

- any loose items

- site offices

The team also laid the crane booms down and ensured the entire area was safe and secure. A final walkdown of the site was conducted with representatives from the Port of Townsville before securing the gates for the day.

Fortunately, the cyclone moved out to sea overnight and the port don’t not sustain any significant damage.

KEY EQUIPMENT USED

Primary Cranes

- 2 x Liebherr LR1300 (300t Crawler Crane)

- Configuration:

- 124T CWT + 57T Carbody CWT

- 47m Main Boom + 20m Luffing Fly

- Liebherr LR1300 (300t Crawler Crane)

- Configuration:

- 124T CWT + 57T Carbody CWT

- 68m Main Boom

Support Cranes

- Liebherr LTM1120-4.1 (120T All Terrain Crane) **FIRST JOB AFTER TAKING DELIVERY

- Liebherr LTM1130-5.1 (130T All Terrain Crane)

- Grove GMK5220 (220T All Terrain Crane)

UNLOADING OF COMPONENTS

Transport equipment

- Components unloaded using ship’s cranes onto Universal Cranes trailers & transported to the assembly yard.

- 4×8 float and 4×8 jinker

- 8×8 platform trailer

Main components

- 67m main beam 115.5T

- 53m derrick boom 90T

- Machine house 78T

- 4x40m legs 38T each